Vesuvius Lite

Vesuvius Lite is an ongoing development project following in the footsteps of the original Vesuvius hotend. Vesuvius lite in particular is intended to fill a lower cost, lower temperature, and smaller footprint role of the market. More or less, we took a lot of the concepts that make Vesuvius perform well, and stuck them into a smaller package that is more oriented towards the consumer market and “speed benchy” printers out there.

Vesuvius Lite still uses an SLM 3D printed heater core, however the heater has been swapped to a flat PTC heater clamped into the block. This allows us to still use some specialized geometry in the heatbreak and transition segments of the hotend to initiate immediate thermal transfer to the filament on all sides while also avoiding some of the legal challenges of cross sectional profile changes inside of the melt zone.

The melt zone on Vesuvius Lite is also shorter than Vesuvius at only around 70mm. This is still quite long of course, but it is closer to the value where a 0.4mm nozzle will see peak flow performance.

Additionally, Vesuvius Lite does not use a second heat zone. This is to reduce the complexity of integration into existing machines so that most users will not need additional control electronics to use this hotend. Additionally Vesuvius Lite is air cooled from the beginning, as it is really not intended to run in high temperature chambers where watercooling is useful.

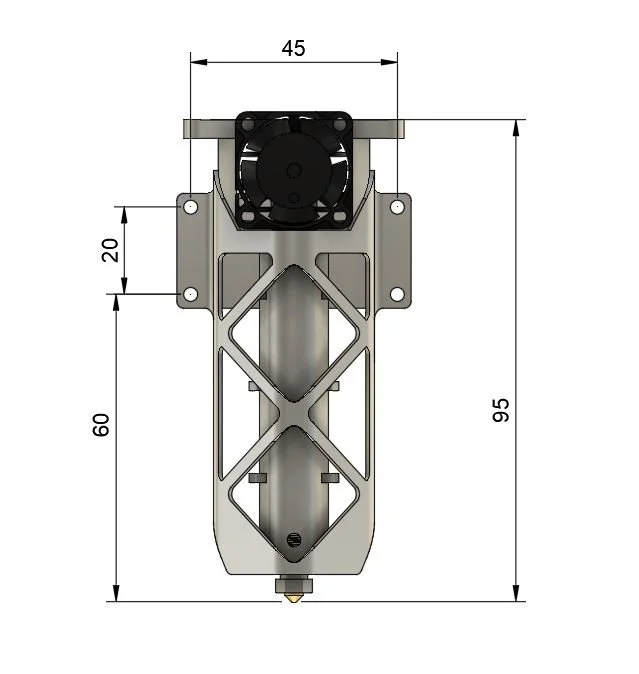

Vesuvius Lite also makes use of a different shroud geometry than the original Vesuvius. Instead of using a tube shaped wraparound shroud, Vesuvius Lite uses a piece of sheet metal that has been formed into shape. This lowers production cost massively while still allowing us to support the end of the meltzone.