Parts Manufactured locally in Southern Michigan

Already know what you need?

Explore our Services

FDM 3D Printing

FDM is ideal for prototype and tooling components out of a wide variety of polymers. Our materials include ABS, ASA, PC, PA6, PP, PPA, PPS, PEI, PEKK, PEEK, and more.

We have a wide variety of machines capable of high production speed and very large components (up to 1 meter).

Resin 3D Printing

Resin 3D printing (SLA, Micro DLP, and Polyjet) is ideal for parts that need a smooth surface finish and high dimensional stability.

We offer several materials; standard (color matching available), Ultra Stiff (high rigidity prototyping resin), Duroprene (tough rubbery material), Ultra Clear (glass like resin), and HT250 (High temperature mold making resin).

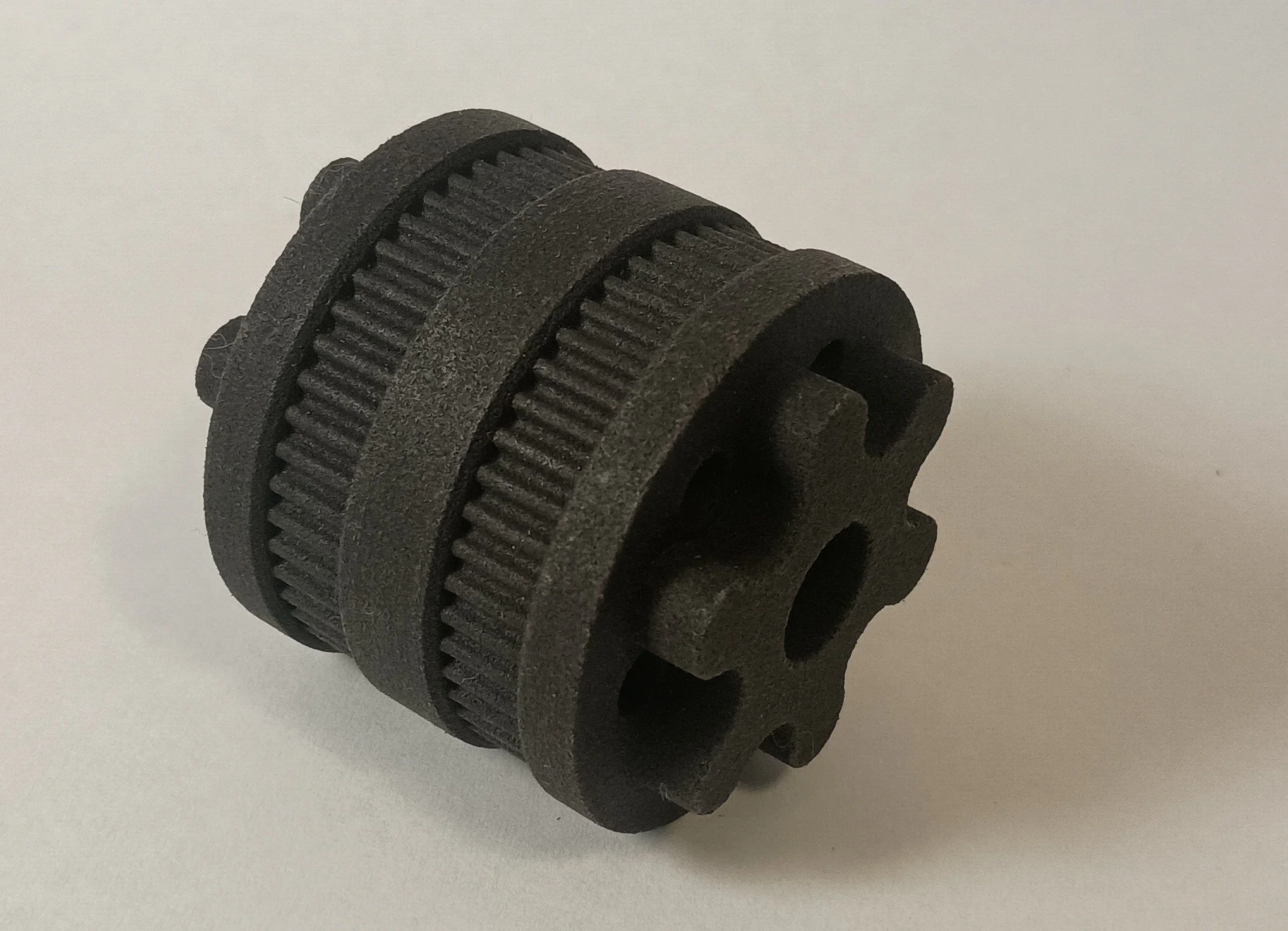

SLS 3D Printing

SLS 3D printing (PA12 nylon) is ideal for end user parts that need to have a pleasant surface finish (consistent rough surface with a sandblasted appearance) and be very high strength.

This process can be used as an alternative to injection molding for small to mid volume production.

Metal 3D Printing

SLM 3D printing is ideal for metal prototypes and small production runs, especially for components that are too complex to be machined or cast from metal easily.

We SLM print in 316L Stainless Steel, AlSi10Mg Aluminum, Inconel 718, Titanium, and (coming soon) M300 steel.

Metal Casting

Metal Casting is a great process for producing large components quickly and at a reduced cost compared to SLM. We work with our own internal tooling production, as well as with customer provided tooling. We can also produce tools for customers to use elsewhere (see our FDM and Resin services)

We can cast parts up to 30Kg in aluminum or a whopping 100Kg of Bronze.

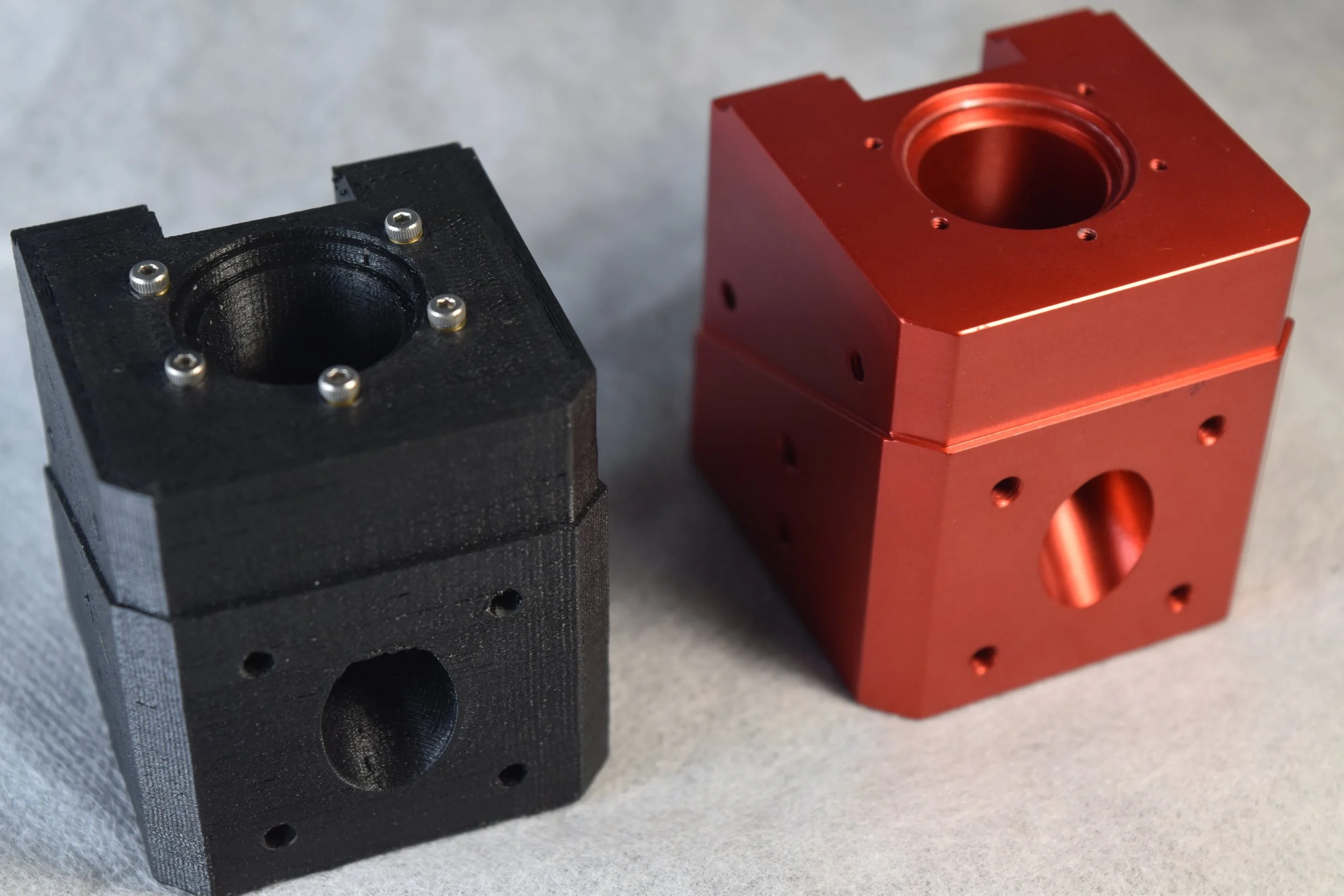

CNC Machining

CNC machining is your classic production method for precision metal and plastic parts. We can cut parts requiring up to 5 axes.

We can cut various metals such as Aluminum, Brass, copper, mild steels, tool steels, nickel alloys, and more. We can also cut other materials such as HDPE, POM, PEI, wood, and composites.

Anodizing

Available as an add on service for our CNC machined Aluminum and Titanium OR as a standalone service for customer supplied parts. Our aluminum anodizing process produces a hard and scratch resistant coating that can be colored to produce a beautiful surface finish.

Titanium anodizing produces a more limited range of colors, but is durable and beautiful.

Laser Cutting

Laser cutting is an ideal process for cheaply producing flat components that can be bent, welded, and processed. For metals, laser cutting results in a much smaller heat effected zone and cleaner edges than plasma cutting.

We can laser cut materials like Steel, Aluminum, Plastics, wood, and more.

PCB Fabrication

We offer PCB fabrication (board production and SMT) services for prototype and mass production. We work with a wide variety of device packages and are able to work with customer supplied components as well as source items ourselves.

Combined with our PCB design services, we can handle the entire electronics development side of your project for you!

From Prototype to Production

we have you covered

With our services and equipment, we are ready to jump in. We have experience in everything from one off components to repair critical equipment, to producing thousands of unique parts in as little as a week.

Domestic Manufacturing made fast and simple

Our engineering background helps us understand how important supply chains are. Being able to source manufacturing locally is essential in safeguarding a small business against unexpected delays and changing market conditions internationally. We are happy to provide our extensive 3D printing, machining, and metal casting services to help other small businesses operate efficiently within the United States and abroad.