Resin 3D Printing

Resin 3D printing is a family of processes where a photopolymer resin is selectively cured using UV light to produce a part. We have 3 main variations of resin 3D printing that we work with; SLA, Micro DLP, and Polyjet.

Depending on your needs, we will help you find the process and material that is the best fit for your parts. Reach out today for a quote, or continue reading for more information!

-

SLA 3D printing is a process where a clear bottomed vat of resin is selectively exposed to a UV light (traditionally with a laser, but MSLA uses an LCD display) to cure each layer of material during printing. This achieves a good resolution (sub 50 micron), smooth surface finish, and works with most materials.

(M)SLA’s main advantage is speed, especially with large quantities of small parts. Since each layer is exposed all at once, print time is purely a function of build height, not part volume or material quantity. As a result, we prefer MSLA for large production runs of small components. -

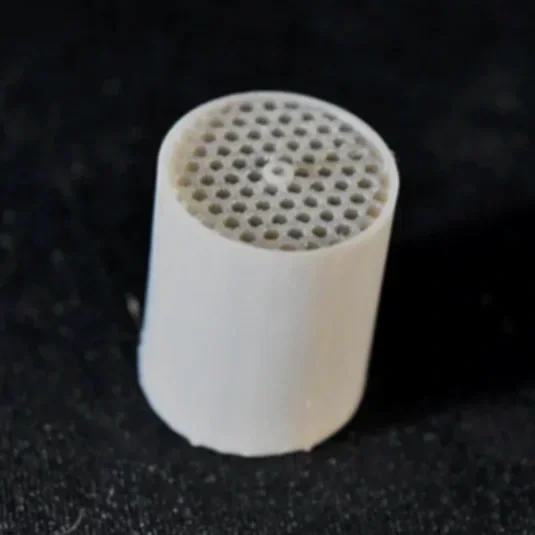

Micro DLP is a technolgy that we developed with the intention of printing very small and fragile parts that would not survive being printed on a standard SLA machine. This is accomplished by projecting an image from a DLP array down onto the surface of a pool of resin to form each layer, making it a fully non contact process. A spreader arm is then used to evenly spread the next layer of resin before exposure.

This process is rather size limited (75×150mm), but can be used to produce extremely intricate parts with a resolution of 10 microns! It can also work with extremely viscous resins and resins that are very fragile or soft when cured. -

Polyjet is a type of 3D printing where an inkjet-like array is used to precisely spray resin onto a part before curing it with a UV lamp. This is able to produce parts in a zero-force process similar to Micro DLP, except on a much larger scale. Polyjet is great for larger functional prototypes of products that need to have near injection molded surface finishes and decent material properties, although it is a bit more expensive than our other resin processes.

Our maximum polyjet part size is 300×150×120mm, making it slightly smaller than SLA but significantly larger than our Micro DLP.

FAQ’s

-

Our maximum resin part size (at the moment) is 400×250×150mm, however this will be increasing soon!

-

It depends. Different materials, part sizes, and quantities will change the price significantly. However, standard materials and parts can start at a few dollars per print, especially in large volume orders. Resin printing scales quite well with volume though, especially SLA, as each layer is exposed all at once. This means that printing 10 identical items on a print bed takes the same time as it would to print 1 item, so the only additional cost is in material use and post processing. When we reach out with your quote, we will tell you the ideal batch size to minimize your per-part price.

When you reach out to us, please let us know all of your constraints (including budget) and what your priorities are so we can help you select the best material and process for the job. -

Our pricing is calculated by a few factors.

Part Mass, which is a rate that covers the cost of material for each part, plus an extra allotment as a safety net in the event of a print failure or if we need to re-do a part for some reason.

Print Time, which covers the cost of electricity, machine maintenance, investment in new hardware, and manpower needed to run the machines. This is a little different for SLA, as additional parts on the same build plate don’t increase print time.

Engineering Time, which covers the wages needed to prepare parts for 3D printing, que files to the machines, and post process prints after they have been removed from the machines.

Urgency, making parts faster than normal requires late hours and re-working of production schedules, which adds to the cost of production.

Quantity, larger orders of parts will cost less per part than a smaller order. This is because we are able to continue production seamlessly instead of having to switch over to new materials, files, and post processing steps which saves time for each part. Savings will vary, but in general the price will always go down as the quantity of an identical part increases.

-

Of course! We understand that most of our customers are not well acquainted with all of the various materials available for Resin 3D printing, so we are happy to provide advice and help select the best material for your use case.

Our goal is to fit you with the right material for the job, so we make a point to not upsell you on a material you don’t need and will point you in a more cost effective direction whenever possible. -

Yes, but with some caveats. We have the equipment and knowledge to produce specialty resin combinations and entirely new formulas for our customers.

We have developed custom conductive/ESD resins, ceramic sinter-able resins, biocompatible resins, foaming resins, and more! If you need unique material properties, we would love to collaborate with you to develop something new.