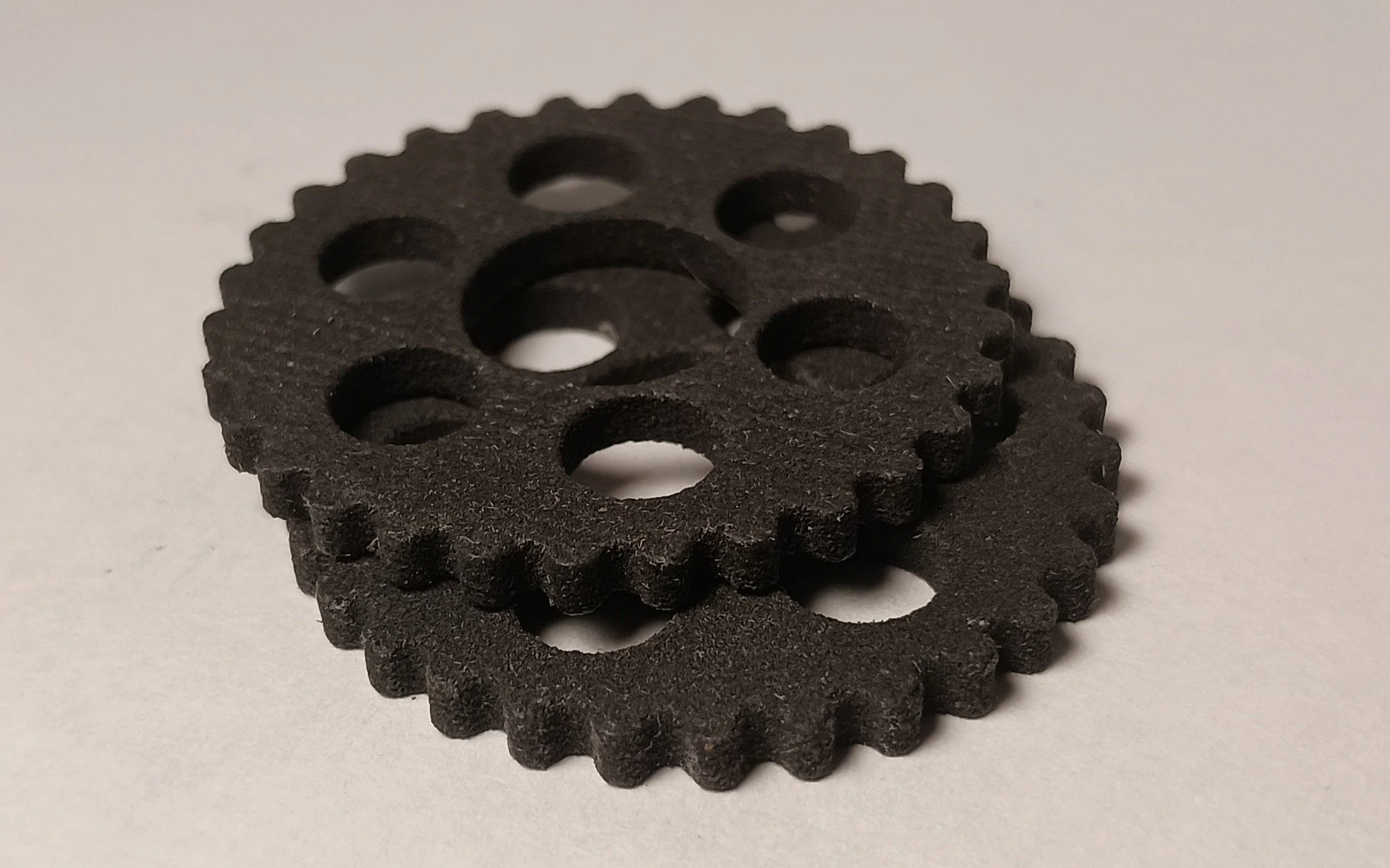

SLS 3D Printing

SLS printing is a process where a powdered material is deposited in thin layers in a build volume before being fused together with a high powered laser. This process results in parts with a very slightly rough texture (similar to sand blasting or powder coating) that makes an excellent surface finish.

The parts are also incredibly strong and homogenous, as well as being low warp. Due to the nature of our SLS process, these parts have a Z strength that is nearly identical to XY strength, unlike typical FDM 3D printing.

-

Our Natural PA12 is a high performance material optimized for toughness. This material is ideal for machine parts that need strength and toughness in all axes, human interface components or control panels that need to have a professional appearance, and automotive components that need high quality material properties with an aesthetically pleasing finish.

PropertiesTensile Strength: 45MPa

Tensile Modulus: 2GPa

Elongation at Break: 18%

HDT (0.45MPa): 145C

Natural PA12 is produced in a white form, but can be dyed various colors depending on your application needs. We dye most components black (it fits well with the surface finish), but can dye components into custom colors upon request.

-

Our PA12-GF is a high performance material optimized for stiffness. This material is slightly less tough than our natural PA12, but has a higher tensile modulus and lower elongation at break. This material is ideal for parts that cannot deform under load.

PropertiesTensile Strength: 45MPa

Tensile Modulus: 2.8GPa

Elongation at Break: 5%

HDT (0.45MPa): 150C

Our PA12-GF prints as a light grey color that can be dyed into a jet black. We can also dye this material into other colors, however this tends to produce colors that are much less vibrant than natural PA12 so it is not something we advise.

-

Our 90A TPU is a semi flexible material that provides options for printing durable and softer parts on an SLS machine. This material is fantastic for components that need to be soft or compliant, but still need the exceptional surface finish of SLM. Some applications where this material really shines are; industrial robotics, wearable technology, covers, cases, shock mounts, and more.

PropertiesTensile Strength: 15MPa

Tensile Modulus:0.08GPa

Elongation at Break 200%:

HDT (0.45MPa): 65C

Our SLS TPU is currently only available in white, as TPU does not uptake dye in the same way as Nylon. We are currently working on methods to add color into these components, so stay tuned for that!

FAQ’s

-

Our maximum part size (at the moment) is a 200×200mm cylinder, however this will be increasing soon!

-

It depends, but small parts will start at a few dollars each in a moderate quantity order.

SLS is a process where the un-sintered powder cannot be reused indefinitely, so it is essential for us to fill as much of the build volume during each print as possible to reduce waste. Because of this, urgent production of a small batch of components that does not fill the build volume will have a higher per-part price than non-urgent production where we can place other customers items into the same print. Additionally, geometries that are primarily hollow will waste additional powder, so even if the parts are lower mass they may not see a massive price reduction. Overall part footprint makes the biggest difference in price with SLS components. -

Our pricing is calculated by a few factors.

Part footprint volume, which determines the amount of parts that can fit in a given build volume at a time. We work hard to optimize nesting to improve efficiency and reduce cost for our customers.

Engineering Time, which covers the wages needed to prepare parts for 3D printing, que files to the machines, and post process prints after they have been removed from the machines.

Urgency, making parts faster than normal requires late hours and re-working of production schedules, which adds to the cost of production. Especially with SLS, this can also result in unfilled prints, which wastes additional powder.

Quantity, larger orders of parts will cost less per part than a smaller order. This is because we are able to continue production seamlessly instead of having to switch over to new materials, files, and post processing steps which saves time for each part. Savings will vary, but in general the price will always go down as the quantity of an identical part increases.

-

Of course! We understand that most of our customers are not well acquainted with all of the various materials available for SLS 3D printing, so we are happy to provide advice and help select the best material for your use case.

Our goal is to fit you with the right material for the job, so we make a point to not upsell you on a material you don’t need and will point you in a more cost effective direction whenever possible.

We also inspect and provide free DFM feedback and limited design services for our customers to help optimize your parts for every process we offer. That way, we can ensure that your parts can be made as reliably, quickly, and cheaply as possible; especially for larger production runs. -

Not with our SLS machines.

SLS is a process that depends extremely heavily on good feed material to function properly. This means an extremely fine and consistent powder that is free of moisture and contamination is required, and any contamination or other issues with the material may result in failures and damage to our machines. As a result, we only work with materials designed intentionally for SLS from reputable suppliers that we trust.