Resin Materials

Resin materials optimized for achieving various different properties and for use in our SLA, micro DLP, and Polyjet machines.

Materials

-

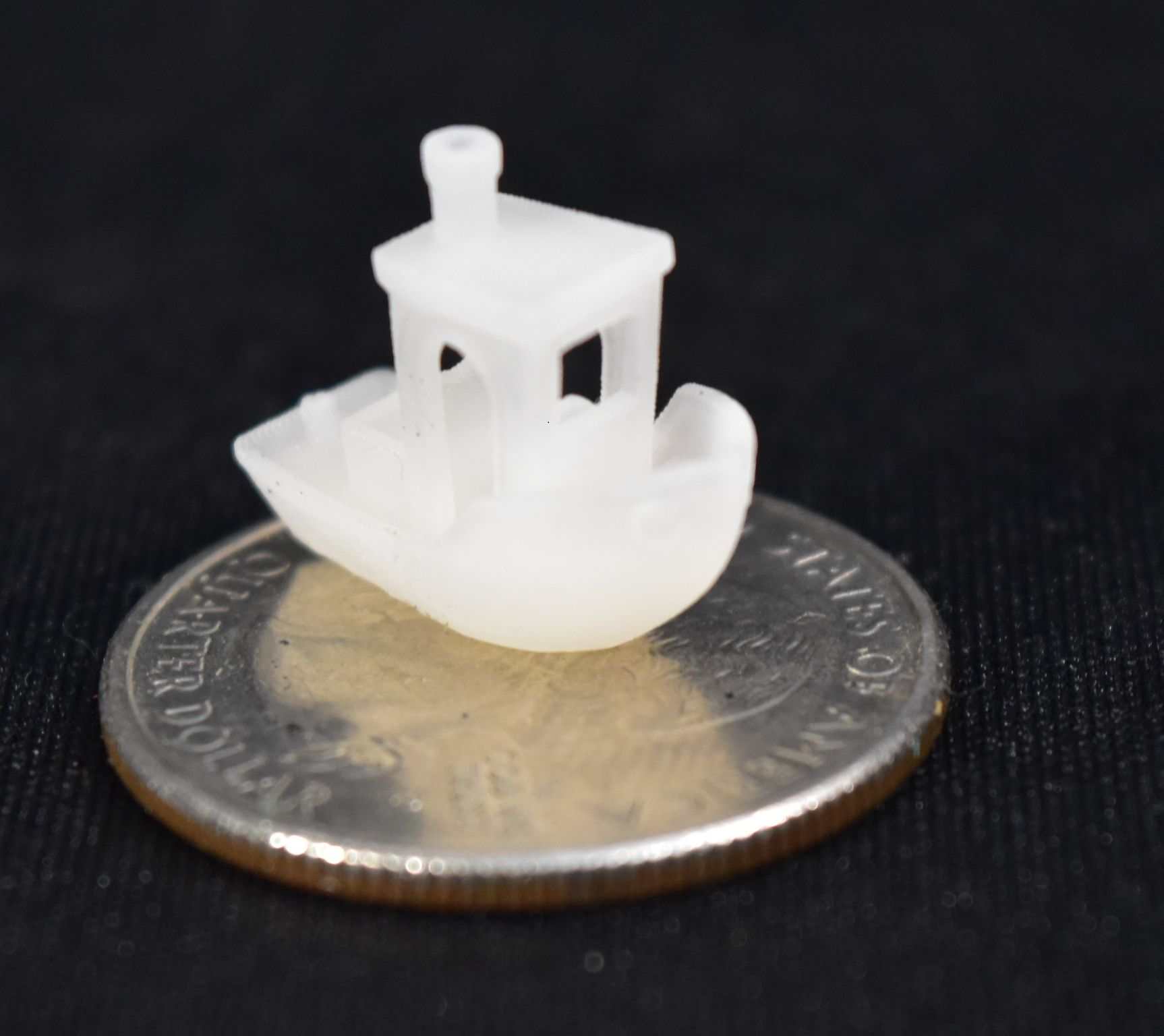

Our Standard resin is made to be inexpensive, print with high detail, and a wide range of color options. This resin is ideal for functional prototypes that do not need exceptional properties and need to look great!

We perform our own in-house color mixing, so we are able to produce parts in any color and nearly any shade. If you have a batch of artistic parts (minifigures, model components, electromechanical devices, props, and more), this resin may be ideal for you.

PropertiesTensile Strength: 45MPa

Tensile Modulus: 2.7GPa

Elongation at break: 10%

Maximum service temperature: 60C

-

Ultra Stiff is a resin with an extremely high tensile modulus, making it perfect for applications where deformation is not acceptable. Items such as fixtures, low temperature molds, forming dies, and aerodynamic models are great applications for this resin.

Ultra Stiff can be colored similarly to standard resin, it is important to note that pigments will slightly change the performance of the resin once cured.Properties

Tensile Strength: 60MPa

Tensile Modulus: 9.5GPa

Elongation at break:1%

Maximum service temperature: 110C

-

Our Tough Resin is designed to plastically deform under shock loads to prevent cracking and damage. This allows for greater energy absorption for components that will undergo shock loads or may be dropped.

Our tough resin is ideal for applications like industrial robot components, automotive prototype parts, fixtures, and anywhere else that requires a moderately stiff material with a smooth finish that is capable of absorbing an impact.Properties

Tensile Strength: 25MPa

Tensile Modulus: 1.1 GPa

Elongation at break: 40%

Maximum service temperature: 50C

-

Our Duroprene resin blend is specifically formulated to mimic the properties of a rubber elastomer. This material is a very soft, grippy, and durable plastic that is exceptionally hard to damage.

It is a fantastic choice for grippers, material handling components, wheels, tires, electronic shock mounts, and much more. If you need custom rubber parts with a smooth surface and high dimensional stability, this may be the material for you.

PropertiesTensile Strength: 8MPa

Elongation at break:100%

Shore Hardness: 60A 80A (tuned per customer request)

Maximum service temperature: 45C

-

Ultra Clear is an acrylic like resin that produces clear parts with an appearance like glass. Ultra Clear is ideal for components that need to allow light through for visual inspection, such as fluid level indicators, waterproof light covers, windows for machines, and more. Ultra clear can be mixed with specific additives to tint the resulting parts to various colors while maintaining clarity.

Ultra Clear has similar material properties to our standard resin. -

HT250 is a resin that maintains it’s stiffness up to high temperatures, making it an ideal material for producing tooling that will be exposed to high temperatures. This resin uses a combination of additives, monomer selection, and post printing heat treatment to achieve a service temperature up to 150C, allowing for contact with hot plastics during forming operations. If you need a vacuum forming tool made, this is the resin to do it with.

PropertiesTensile Strength: 48MPa

Tensile Modulus: 2.6GPa

Elongation at break: 3%

Maximum service temperature: 150C

-

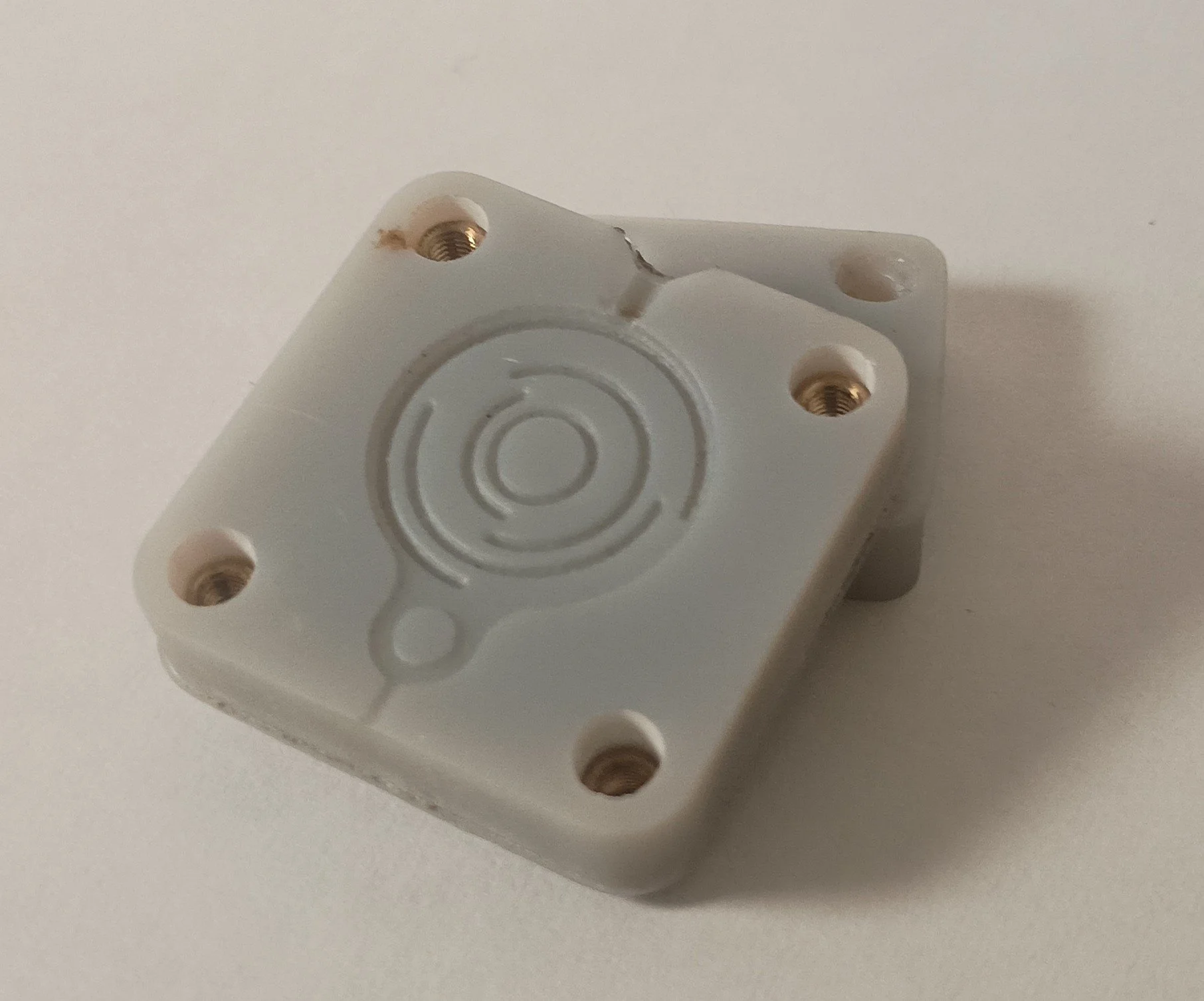

HT250 is a resin that maintains it’s stiffness up to very high temperatures, making it an ideal material for producing injection molds for prototyping or small production runs. This resin uses a combination of additives, monomer selection, and post printing heat treatment to achieve a service temperature up to 250C, allowing for direct contact with many molten thermoplastics such as ABS. If you need a quick injection mold prototype made, this is the resin to do it with.

PropertiesTensile Strength: 45MPa

Tensile Modulus: 2.8GPa

Elongation at break: 3%

Maximum service temperature: 250C

-

Our burnout resin is intended for producing molds for metal casting, as it is able to cleanly burn away leaving behind a high quality shape in an investment or hard sand mold for metal to be poured. It is not very strong or durable, but it is sturdy enough to survive the sprueing and investment pouring process to produce high quality metal parts.

Combined with our in-house metal casting services, we can use this material to produce you custom metal parts in nearly any geometry you may need.